New, resilient material – Carl ROTH

New materials with additional functions hold enormous potential to make various technical and industrial applications not only more functional but also more sustainable. We have explored the fascinating world of materials science for you; here we present some examples – from the automotive industry to medical technology.

For a long time, multitasking was on trend and considered an important “soft skill” for an efficient, successful life. In the age of work-life balance and self-care, some have opted to do the exact opposite: “rawdogging” which, among other things, refers to monotasking. Practitioners consciously avoid distraction and diversion, nor do they try to accomplish as many things as possible at the same time, instead focusing fully on the one task before them. For example, looking out the window, and not listening to a podcast at the same time. To be fair, that also sounds exhausting, and some may still long for the good old days of multitasking.

In the inanimate world, fortunately, no one has to worry about overload. On the contrary: multitasking is still very much on trend here, and can be extremely useful. For years, researchers have been trying to develop materials that they can endow with new or additional properties. And for good reason – because new materials can make areas such as construction, transportation, the electronics industry, information technology and medical technology not only more functional but also more sustainable. They enable the development of more resilient, durable and smaller components, which saves raw materials and energy. If the car paint not only looks good and protects against corrosion, but also repairs itself when needed, it lasts longer and does not need to be repainted. The same applies to implants that are coated in such a way that only certain cells adhere to them, in order to suppress rejection reactions. Other new materials are just as durable as the established ones, but can be produced from renewable raw materials or are particularly easy to recycle. This also saves on valuable resources, offering added sustainability. The world of “multitasking” new materials is highly diverse and fascinating. Here we present some selected examples.

Self-healing paints and lacquers

Slipped while refuelling your new car? Even micro-fine scratches in the paint are annoying, and can decrease the value. Researchers at the Leibniz Institute for New Materials (INM) in Saarbrücken have developed a topcoat that can ‘heal’ superficial scratches when heated to 90 degrees Celsius for one minute with a hot air gun, for example. The twist: the paint contains long-chain plastic molecules onto which cyclodextrins – ring-shaped derivatives of corn starch – are threaded. In the polyrotaxanes thus formed, the cyclodextrins are freely movable over certain segments on the plastic thread. Through a chemical reaction, the bead chains are cross-linked with each other. “The resulting network is as flexible and elastic as a stocking”, explains Carsten Becker-Willinger, head of the Nanomere programme area at INM, in a press release. When exposed to heat, the cyclodextrin beads move along the plastic fibres back to the area of the superficial scratch and fill in the gap created by the scratch. For a functional coating with higher mechanical stability and weather resistance, researchers at INM altered the composition of the polyrotaxanes by adding additional ingredients, such as heteropolysiloxanes and inorganic nanoparticles. They were thus also able to reduce the repair time from several hours to just a few minutes.

The same goal of self-healing surfaces is being pursued by a research group from the Fraunhofer Institute for Production Technology and Automation (IPA) and the Fraunhofer Institute for Applied Polymer Research (IAP). The researchers are using so-called microcapsules. These are incorporated into the paint and contain an active substance. If the paintwork is damaged, the capsules burst, the active substance is released, and the paintwork ‘heals’ or the scratch does not spread further. “In general, the capsules consist of a core and a wall material. The core material is usually an active substance that is released later. Self-healing surfaces can be corrosion inhibitors, lubricating oils, adhesive components or combinations of these three active substances. The wall material can consist of cross-linked or non-cross-linked polymers, but also of inorganic silicon or titanium dioxide and their combinations”, explains Alexandra Latnikova from the Fraunhofer IAP during an interview. It sounds simple, but far from it. The capsules are usually produced using so-called melamine resin technology based on a precisely engineered emulsion. The incorporation of microcapsules into the matrix can also be challenging. On the one hand, you want to create capsules that open at the right moment; on the other hand, they should be as robust as possible during processing, meaning they shouldn’t ‘activate prematurely’. The dispersion technology used in this process – mixers, rollers or rotor-stator homogenisers, depending on the coating – must therefore be chosen very carefully. The density and size of the microcapsules, as well as their surface properties, must also be correct for them to be evenly distributed in the coating.

Nature as a great model for new materials

That nature provides excellent role models in many ways is nothing new. When it comes to novel materials, bionics has been drawing from its toolbox for years and has already brought many innovations to market, ranging from bionic lightweight components derived from bird bones to self-adhesive surfaces inspired by gecko feet, and even coatings with a lotus effect that repels water. And another has recently been added: the door handles in the VISION EQXX concept vehicle from Mercedes-Benz are made from a fabric derived from biotechnologically produced spider silk proteins, classified as vegan and certified to OEKO-TEX® Standard 100, as well as for biodegradability in line with OECD 301B. A young company called AMSilk from Neuried, a spin-off of the Technical University of Munich, has developed the fibres for the fabric and produces them using a scalable spinning process.

In terms of tensile strength, the fibre is comparable to natural spider silk, which is why AMSilk calls it Biosteel. The strongest natural spider threads are actually more tearproof than steel threads of equivalent thickness. The spider silk rope has a tensile strength of about 1100 MPa, which is weaker than a Kevlar thread (3600 MPa), but it can be stretched up to 30% – more than ten times more than Kevlar. The slightly weaker threads that spiders produce for their webs can even achieve an elasticity of 270%. Genetically modified bacteria could provide silk proteins with the desired tensile strength and elasticity in consistent quality and large quantities in the future.

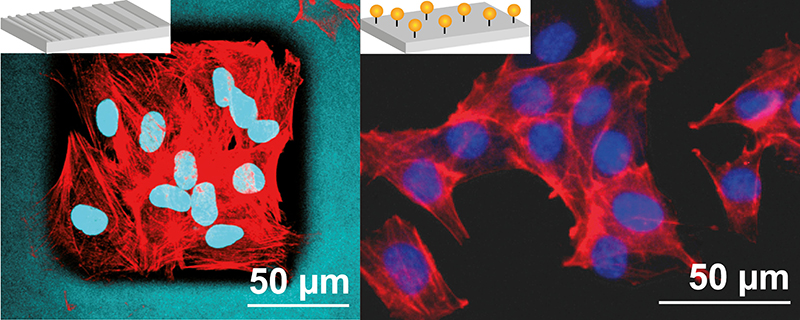

Since materials made from biotechnologically produced spider silk are not only particularly tearproof and elastic but also biocompatible, they can additionally be used for biomedical purposes, such as designing scaffolds to promote natural regeneration processes, coating implants or even 3D printing hydrogels with encapsulated cells that can be further processed into functional materials. Researchers led by Thomas Scheibel from the University of Bayreuth have discovered that these materials can be modified or processed to ensure that only specific cell types can adhere to them and grow and multiply on them.

As the researchers determined, silk proteins can be functionally modified through the targeted incorporation of specific peptides, resulting in cell-specific effects in the materials created from them. Cell-interacting (cell-adhesive) peptides, for example, are found in the extracellular matrix (ECM) of natural tissues, a lattice-like molecular structure that fills the spaces between adjacent cells and stabilizes their spatial arrangement. The scientists from Bayreuth incorporated frequently occurring cell-adhesive peptides into several variants of a silk protein, a ‘derivative’ of the European garden spider’s silk. As a result of the molecular modification, some of these modified silk proteins proved to be cell-adhesive, while others exhibited cell-repellent behaviour. In some cases, however, cell-specific interactions were also observed. For example, a specific peptide specifically promoted the attachment and growth of myoblasts, embryonic muscle precursor cells that can develop into muscle fibres.

Author: Vanessa Trossmann, Image source: https://idw-online.de/de/news813626

The research team led by Prof. Dr Thomas Scheibel also used a lithographic process to structure the surface of these coatings in such a way as to specifically stimulate the attachment and growth of a certain type of cell. “Based on the results of our research, it will be possible to lithographically optimise coatings made of silk proteins – or other biocompatible materials – in such a way that they stimulate and promote the natural regeneration of complex tissue structures in a cell-specific manner”, says Scheibel in a press release. “The body’s rejection reactions to implants could also be suppressed in this way. Here, sustainability is achieved in two ways: for materials and resources as well as for the patient.

These are just a few examples from an almost infinite range of possibilities. When it comes to ‘multitasking’, materials science has by no means exhausted its ideas, and we can look forward to exciting developments in the field of new materials in the future.

You can findmore interesting new

and resilient materials in carl 02.

Sources:

https://blaetterkatalog.carlroth.com/CARL_2302_EN/

https://www.amsilk.com/biosteel-fibers-receive-certification-for-product-safety/